Calculate the overall heat transfer coefficient. Divided by the inlet pressure p v c von 1000 Pa we obtain a pumping speed S 1 von 0397 m 3 s -1 or 1429 m 3 h -1.

Condenser Design 1 0 1 Free Download

Q p v c S 1.

. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a. The following design parameters for the condenser were calculated based on the values entered on the. From Thermal design calculations of Shell.

Air Cooled Condenser. Condenser sizing How to design a shell-tube condenser. So Basically to define the heat transfer of any heat exchanger we will go.

Support SI UnitsEnglish US Units of measurement Units converter containing 23 measurements and 200 units. Calculation of Condenser Heat Load. Lets start our design concept Once again recollecting duty of condenser is to take off the latent heat from vapour and condense them so the load over a condenser will be Latent heat Latent Heat QL M x Lam.

Heat exchanger design handbook Juan Guillermo. The first step is to calculate the gas flow from the chamber. This software can design horizontal shell side condensers horizontal tube side condensers vertical shell side condensers vertical tube side condensers and reflux condensers.

The water used for cooling has the following data. Quantities of VOC in Inlet and Outlet streams. These templates use SI.

Free Excel condenser calculation tool. We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plantsIn systems involving heat transfer a. Condenser Design Calculation Pdf To Excel 7710 4225votes.

Air Cooled Condenser Design Spreadsheet - Download as Excel Spreadsheet xls PDF File pdf. Condenser Design Calculation Pdf To Excel. Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being done by.

M - Mass FlowRate of vapour Lam - Latent Heat of Vapour. Results cells should use a different color scheme than inputs and also be easy to spot. These values were used to prepare the costs shown on the Cost Estimate.

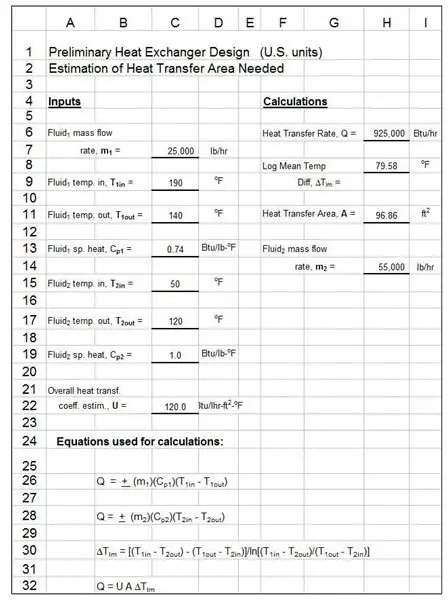

Calculate the heat transfer surface area. The heat transfer area can be calculated after values have been determined or estimated for the required heat transfer rate Q. For sizing a heat exchanger several thermal phenomena should.

Units U is the overall heat transfer coefficient in Btuhr-ft 2 o F kJhr-m 2 -K for SI. MJCronin Mechanical 2 Jul 19 2338. FOR EDUCATIONAL PURPOSE ONLY DO NOT USE THIS METHOD FOR DETAIL DESIGN ALWAYS CONSULT A REPUTABLE SUPPLIER FOR DETAIL DESIGN Condenser sizing calculation tool Input Results Orientation Heat exchange area m2 Condenser Horizontal Number of tubes Tube length m Tout Tin Cooling fluid Number of passes.

Many features including exporting to engineering data sheet. Shell and Tube Condenser Design with Condenser Design CnD software. The basic heat exchanger design equation is.

Equations and Parameters The heat exchanger design equation Q U A ΔT lm can be used to determine the required heat transfer area A for a heat exchanger. Calculate the required heat transfer area based on values needed. Condenser design Igwe Johnson.

Import physical properties data to hot side and cold side from Microsoft Excel from WeBBusterZ Physical. Realize that the design of your steam surface condenser must fit into the thermal design of your plant. This software incorporates many of the thermal.

Q U A ΔT lm where. We obtain a gas throughput for air of 12 Pa m 3 s -1 and for water vapor of 385 Pa m 3 s -1 together 397 Pa m 3 s -1. Thermal design calculations of Shell.

Design A Shell Tube Heat Exchanger On Ms Excel - posted in Process Heat Transfer. Specifying Steam Surface Condensers. The first step of the analysis has been the design calculation of the condenser main.

1 Evaporation cooling Thermocompressor design. You can access a free Excel calculation tool to size a shell-tube condenser or control the size of an existing condenser as explained above. Units ΔT lm.

Condenser design calculation tool. Calculate the capacity rate ratio. Wet steam temperature is 37 C and enters the condenser with 095 quality dryness fraction is 095.

Quantity of VOC Recovered. Support SI UnitsEnglish US Units of. The software also includes a basic physical properties.

This tool is not validated for detail design it is only to illustrate the concepts shown on this website. Calculate temperature at the cooling box for given mass flowrate of motion steam. Design of condenser 1.

Calculation of condenser heat load is. This software can design horizontal shell side condensers horizontal tube side condensers vertical shell side condensers vertical tube. Surface condenser design calculation.

Download Condenser Design for Windows to perform thermal design calculations for shell and tube condensers. Q the rate of heat transfer between the two fluids in the heat exchanger in Buthr kJhr for SI. Design of condenser 1.

The condenser coupled with the corresponding fan and characterized by four rows of finned tubes while the third one refers to a condenser composed of 21 modules 18 parallel-flow and 3 dephlegmator with three tubes rows. - Inlet pressure 120 bar inlet temperature 7 C - Outlet pressure 1013 bar outlet temperature 22 C Calculate the flow rate. Calculate the length of the tube or heat exchanger.

Also it is best if all cells where input data is to be entered are highlighted and easy to spot. Data Sources for Default Values Used in Calculations. Up to 24 cash back Condenser design CnD is a software tool that is made to demonstrate the thermal design calculations of Shell Tube condensers.

Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations. June 30 2018 September 6 2019 hiadmin Heat Exchanger 28 Comments on Air Cooled Condenser. A surface condenser is required to deal with 15 000 kgh wet steam.

All these calculations should already have. Condenser Calculation Using Thermo Utilities MS Excel Add. Wet steam temperature is 37 C and enters the condenser with 095 quality dryness fraction is 095.

Units A is the heat transfer surface area in ft 2 m 2 for SI. The overall heat. Condenser Design has had 1 update within the past 6 months.

Air cooled condenser design calculation excel. Condenser Design Calculation Excel. Calculation of Enthalpy of Condensation.

CnD is a software that is made to demonstrate thermal analysis and design calculations required for designing shell and tube condensers. This software application is intended for use by professional and academics in the engineering industry. I am new to this website I wanted to share a few spreadsheets dont know whether this where I should share the file or not.

Steps for design of heat exchanger Calculate the effectiveness. The software can design horizontal condensers vertical condensers including reflux condensers. For cases where a small finite number of entries is possible for example tube diameters pulldown lists are a nice touch.

The thermal design of the typical steam plant is done by analysis developed specifically for power plant design.

Suspension Bridge Is A Spreadsheet In Excel 48 94 Kb Bibliocad Suspension Bridge Spreadsheet Excel

Xls Condenser Design Karunamoorthy Ramamoorthy Academia Edu

Condenser Design Calculation Excel

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

0 comments

Post a Comment